Identify energy and cost savings that can be achieved through industrial insulation

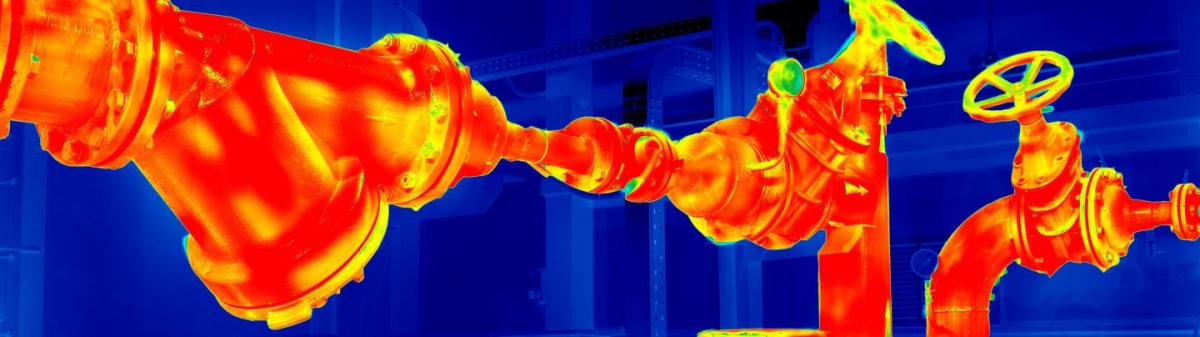

The energy saving potential of insulation in industry is significant, but insulation is still lacking in many production facilities. TIPCHECK auditing reliably identifies the energy and cost savings that can be achieved through industrial insulation. ISOPARTNER wants to reduce our climate impact by insulating intelligently. There is significant potential for energy savings and CO2 mitigation by improving thermal insulation in industrial installations. Due to higher temperatures faced by industry, there is more importance on the role that good technical insulation plays in controlling heat loss. In addition, studies by EiiF have found that a significant proportion of low-temperature (50–100 °C) sites are completely uninsulated and therefore have a high potential for energy savings. This potential is currently untapped despite being cost-effective to implement.

TIPCHECK benefits to the industry

The TIPCHECK Programme delivers multiple energy and non-energy benefits to the energy user, the supply system and the economy. Industrial insulation is a proven technology delivering multiple benefits:

• Reduces energy and production costs

• Increases energy efficiency

• Reduces CO₂ emissions

• Improves process efficiency

• Reduces safety risks for personnel and equipment

• Increases competitiveness

• 75% of TIPCHECKs lead to insulation investments

• The payback periods for the initiated TIPCHECK insulation projects were in most cases 2 years or even less.

How do we conduct the TIPCHECK audit?

The TIPCHECK is performed by certified experts and consists of several steps.

During the start-up meeting, the scope and goals of the project will be defined in cooperation with the customer. All relevant information is then gathered by us.

Next is the field work, where the inspection is performed. We will analyze the current situation of the insulation and the necessary measures.

Based on these findings, the potential savings will be calculated with the TIPCHECK tool. These observations will be written out in a detailed TIPCHECK report, which will then be presented to the customer.

The road to becoming TIPCHECK certified

The EiiF (European Industrial Insulation Association) provides training for energy auditors to provide tools and solutions for saving energy in the industry and reducing CO2 emissions by improving insulation solutions.

The training enables to evaluate the performance of the current insulation system and present better insulation solutions to save energy and reduce CO2 emissions. It is an intensive contact teaching period of five days plus a few additional training sessions. Those who pass the training are called EiiF-qualified TIPCHECK engineers.

For example, a TIPCHECK engineer can calculate the savings potential of a plant or plant in terms of money, energy or carbon dioxide emissions, and present insulation solutions to achieve that potential. TIPCHECK engineering training is high-quality training based on international standards, and graduates also have access to a reliable, standardized energy auditing tool.